State of the Art Manufacturing, Engineering and Repair Facility

- Parts and repairs for all OEM Steam Turbines

- ISO 90001 and AS9100 Certified

- over 250,00 sq. ft. manufacturing and repair capability over 5 facilities

- 24/7 Operation

- $5M of in-stock material and 1,000’s of in stock parts

- Expedited delivery. Can manufacture most parts during short cycle major inspections-

- Reduce Maintenance Budget!- No Need to Stock Overhaul Parts

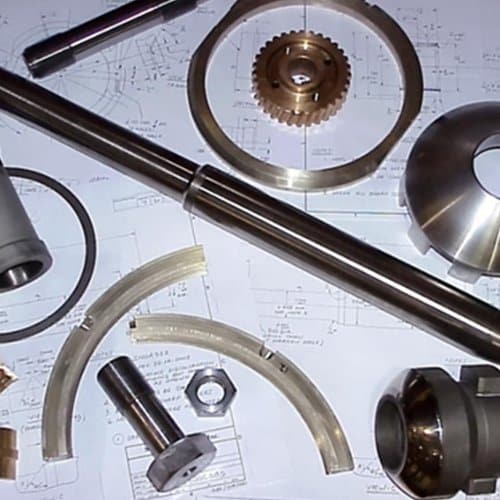

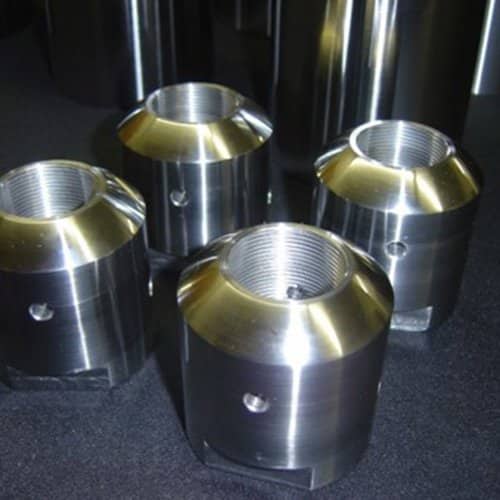

Steam Turbine Valve Components for all OEM’s

- Valve bodies, complete valve manufacturing if needed

- Valves stem, seats, pins, bushings and discs

- Valve disc caps, bolts and disc staking groove repair

- Main stop valve steam and seal head assembles for easy drop in replacement

- Crossheads

- Lift rods, lift bars and single piece an 2 piece valves for bar lift valve assemblies

- Spool valves, cages and lift rods

- Cams, camshafts and camshaft bearings

- Camshaft bearing upgrades

- Cam rollers, pins, bushing and bushing upgrades

- Rack and pinion gears

- Piston rings

- Gaskets

- Steam strainers

- Non return valve, stems, bushings, clappers discs and pneumatic cylinder rebuilds

- Valve try bars

In Shop and Site Services

Overhauls and Rebuilds for:

- All size and OEM Steam Turbines, Gear Boxes and Generators both in Shop and at Site

- Trip Throttle Valves

- Main Stop Valves

- Combined Reheat Valves

- Non Return Valves

- Individual Control Valves

- Inlet and Extraction Control Valve Racks

- High and Low Pressure Operating Cylinders and Rams

Welding, Coating, and Hardening Processes

- Stellite Welding-Automated and Manual

- Plasma/Ion/Gas Nitriding

- Flame and Induction Hardening

- HVOF and Ceramic Coatings, Flame and Plasma Spraying

- Heat Treating and Stress Relieving

- Electron Beam Welding

- Quenching, Tempering and Annealing

- Caburizing-All types

- Anodizing

- All Types of Welding

- 24/7 Operation

- Certified in All NDE/NDT Processes

Engineering and Manufacturing

- Creaform Laser Scanning

- Photogrammetry

- Laser Tracking

- Certified Alloy Analyzing

- Portable Coordinate Measuring Machine (CMM)

- Solidworks Suite

- Computer Aided Design (CAD)

- CNC programming

- Computer Aided Manufacturing (CAM)

Contact Information

Steam Turbine Solutions, Inc.

PO Box 871, Bolton, MA 01740

(978) 751-1857

info@steamturbinesolutions.com

10 YEARS OF EXCELLENCE!

What is STS, INC?

Steam Turbine Solutions, Inc. is a turbine technical support, engineering and parts supplier that is committed to helping their clients operate as efficiently and reliably as possible. Our expertise will help you troubleshoot your operational issues, plan your parts purchase for your next outage and insure you get the highest quality parts for the lowest cost and the fastest delivery.

MEMBERSHIPS

Member of US DOE EE & RE

Steam System

Assessment Steering Committee since 2006